In today’s technology-driven industries, machines play a critical role in maintaining productivity and operational efficiency. Whether in manufacturing, printing, packaging, or industrial production, the performance of machines directly impacts business success. This is why reliable service solutions such as Machine Repair and SMachine Repairupport and professional training services are essential for long-term operational stability.

When machines function efficiently and operators understand how to use them correctly, businesses experience fewer breakdowns, reduced costs, and improved output quality.

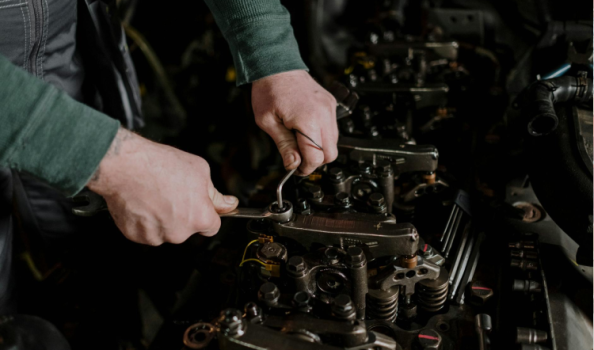

Modern machines are complex systems that require expert handling. Even minor issues, if ignored, can lead to costly downtime or permanent damage. Professional service providers ensure that machines are inspected, diagnosed, and restored using industry-approved techniques.

Preventive maintenance, timely troubleshooting, and expert repairs help extend the lifespan of equipment. Businesses that invest in proper service solutions are better equipped to meet production deadlines and maintain consistent quality standards.

Machine Repair and Support refers to a complete service solution that includes diagnosing faults, repairing damaged components, replacing worn-out parts, and providing ongoing technical assistance. These services are designed to keep machines running smoothly and efficiently.

Support services also include emergency repairs, software updates, calibration, and performance optimization. With expert technicians available, businesses can minimize disruptions and maintain continuous operations without unnecessary delays.

Even the most advanced machines require skilled operators. Incorrect usage often leads to mechanical failures, reduced efficiency, and safety risks. This is where structured training programs play a vital role in operational success.

When operators are properly trained, they understand machine functions, safety protocols, and basic troubleshooting techniques. This reduces dependency on emergency repairs and enhances overall workplace safety.

Machine Training and Support focuses on educating operators and technical staff on proper machine usage, maintenance routines, and operational best practices. Training can be conducted on-site or through structured programs tailored to specific machine models.

Support services include user manuals, technical guidance, performance monitoring, and ongoing assistance to ensure that operators remain confident and competent in their roles.

Businesses achieve the best results when repair services and training programs work together. Technicians fix mechanical issues while trained operators prevent recurring problems. This combination improves machine reliability, reduces repair frequency, and lowers long-term operational costs.

Additionally, trained staff can quickly identify early warning signs of malfunction, allowing timely intervention before major failures occur.

Industries such as manufacturing, printing, textiles, packaging, and automation heavily depend on machine service solutions. These sectors require consistent machine performance to meet production targets and customer expectations.

Whether it is a small business or a large industrial operation, having access to expert support and training ensures uninterrupted workflow and operational confidence.

As machines become more automated and software-driven, service solutions will continue to evolve. Businesses that invest in both Machine Training and Support and technical repair services will stay ahead of operational challenges.

In conclusion, professional machine services are not optional—they are a strategic investment. Reliable repair solutions combined with skilled operator training ensure efficiency, safety, and long-term business growth.